Our Products

- Crash Barrier

- Thrie Beam Highway Crash Barrier

- W Beam Highway Crash Barrier

- Metal Beam Highway Crash Barrier

- Highway Guardrail

- W Beam Guardrail

- High Mast Pole

- Octagonal Pole

- Conical Pole

- Steel Tubular Pole

- Non Woven Geo Textile

- Geo Grid

- Thermoplastic Road marking Paint

- Road Stud

- Road Delineators

- Spring Post

- Road Speed Breaker

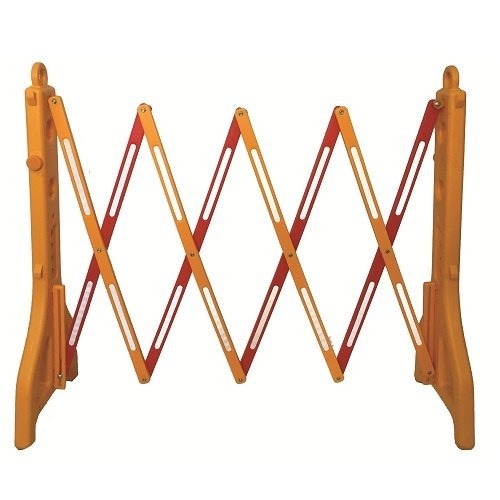

- Scissor Barrier

- Water Barrier

- Traffic Cone

Non Woven Geo Textile

Non-woven geotextile is a type of synthetic fabric designed for various civil engineering and construction applications. It is used to provide reinforcement, separation, filtration, and drainage in soil and geotechnical projects. Non-woven geotextiles are made from polyester, polypropylene, or other synthetic fibers that are mechanically bonded together, creating a fabric that offers specific properties suited for improving soil stability and performance.

Key features and aspects of non-woven geotextile include:

Material: Non-woven geotextiles are made from synthetic fibers that are mechanically or thermally bonded. The fibers can be made of polyester, polypropylene, or a combination of materials.

Applications: Non-woven geotextiles are used in a variety of applications, including:

Separation: They prevent the mixing of different soil layers, such as when placing gravel over soft soils.

Reinforcement: They enhance soil stability by providing tensile strength and improving load distribution, commonly used in road construction and embankments.

Filtration: They allow water to pass through while preventing the movement of fine soil particles, used in drainage systems to prevent clogging.

Erosion Control: They help control soil erosion by stabilizing soil surfaces and preventing water-induced erosion.

Protection: They provide a protective layer for geomembranes, liners, and other sensitive materials in various applications.

Strength and Durability: Non-woven geotextiles have good tensile strength and resistance to tearing, making them suitable for reinforcing soils and stabilizing structures.

Permeability: They can have controlled permeability, allowing water to flow through while retaining soil particles. This property is important for drainage and filtration applications.

Thickness and Weight: Non-woven geotextiles are available in various thicknesses and weights to suit different project requirements and soil conditions.

UV Resistance: Some non-woven geotextiles are treated with UV stabilizers to ensure they withstand prolonged exposure to sunlight without degrading.

Installation: Non-woven geotextiles are easy to handle and install. They can be laid directly on the soil or incorporated into the construction layers as needed.

Cost-Effectiveness: Non-woven geotextiles are often more cost-effective than natural alternatives and can provide long-term benefits by improving soil performance and extending the life of structures.

Environmental Considerations: Non-woven geotextiles are inert and do not release harmful chemicals into the environment. They are widely used in environmentally sensitive areas.

Quality Control: Non-woven geotextiles are manufactured to meet industry standards and specifications, ensuring consistent quality and performance.